Corrugated Stacker Solutions

High Performance. High Throughput.

Discover the high performance corrugated stackers from our partner A.G. From their G3™ stacker to the eSERIES™ line, innovation comes standard on all A.G. systems. Contact our team today to discuss your production needs!

Made in the USA

Patented technology

No pits!

Automatic Set Up

Intelligent Safety System

Digital Tech Enabled

Ergonomic Design

Expert Service & Support

G3™ Corrugated Stacker

Stacker innovation optimized for performance, speed and control.

The versatile G3™ corrugated stacker is available in the following sizes:

115”

125”

Up to 13,500+ KPH

Full Stack or Bundle Line

4-Out Capability

Standard Features

High Performance Layboy

Air Operated Deck Lift

Flexi Deck

Ventilated Vision Backstop

Tampers & Dividers

Side Catchers

Remote Diagnostic System

Carriage Style Snubbing Wheels

Accumulator Back Tamping

Pivoting Hopper Guides

Scrap Release Technology

Order Memory System

Integrated Safety System

Stacker Upgrades

HIGH-SPEED HOPPER EJECTOR (HSHE)

SAMPLE QUALITY REJECTION (SQR)

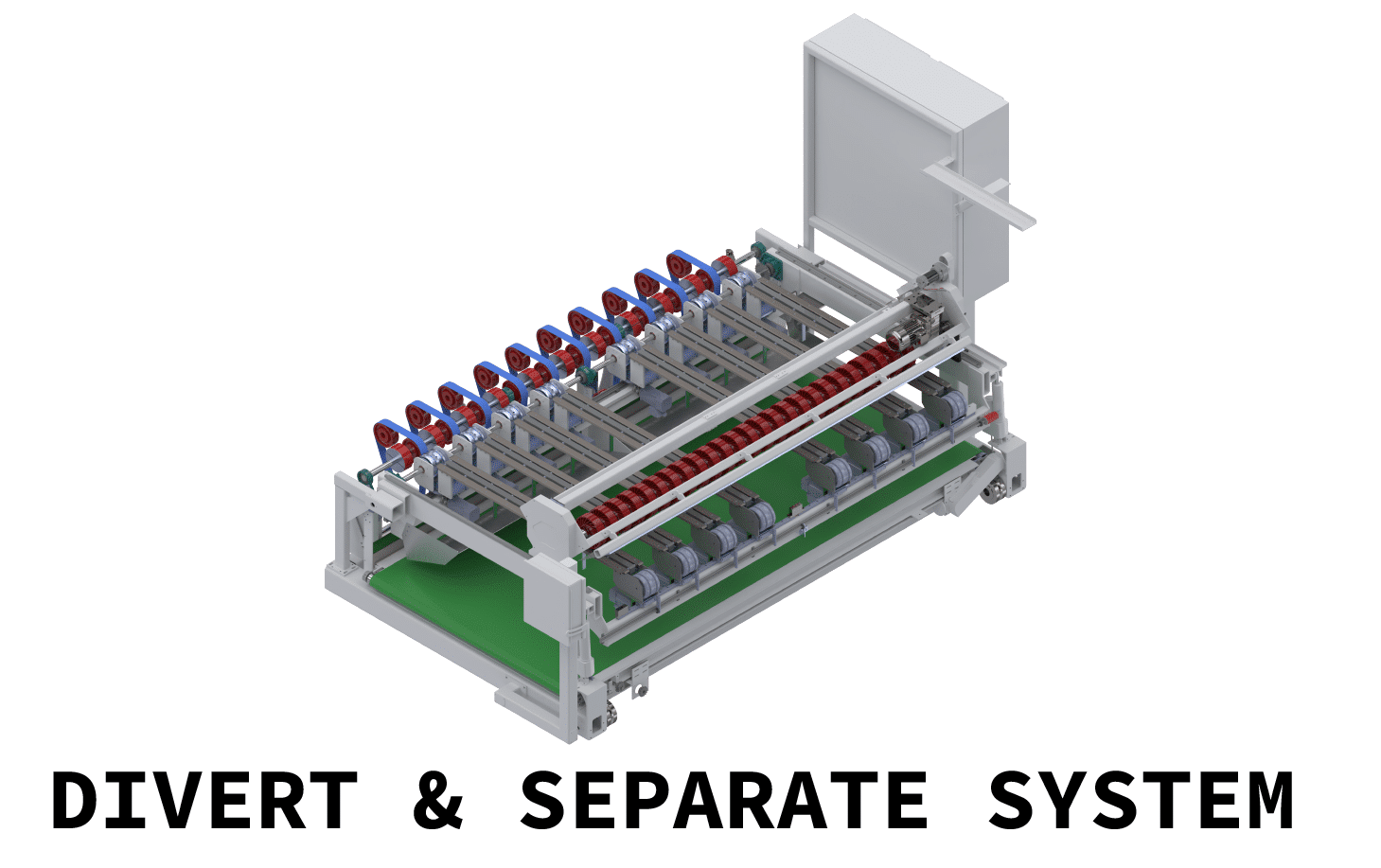

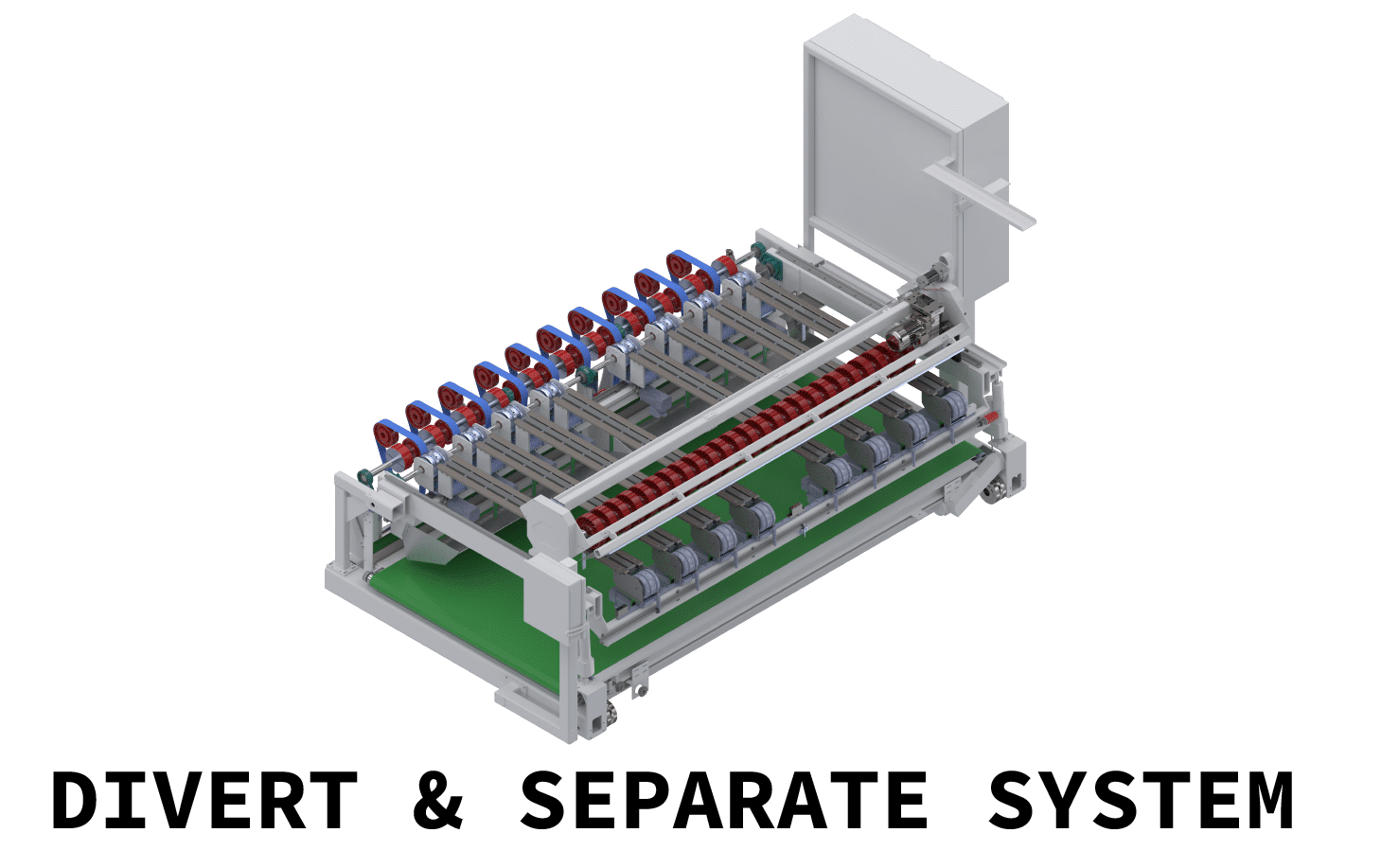

DIVERT & SEPARATE SECTION (DSS)

SRX Scrap Release Layboy

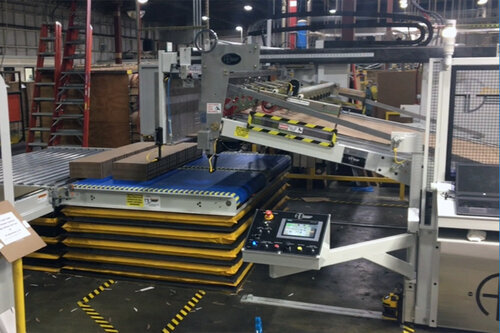

ePX Semi-Automatic Pallet Inserter

Divert and Separate System (DSS)

Servo Driven Tampers (eTAMP™)

Sample Quality Rejection System (SQR)

High Speed Hopper Ejector (HSHE)

SERVO DRIVEN TAMPERS (eTAMP™)

XRI™ Corrugated Stacker

Innovative design and heavy duty construction.

An investment that will last decades.

The XRI™ corrugated stacker is a piece of versatile corrugated stacking machinery available in the following sizes:

115″

Up to 13,500+ KPH

125”

Full Stack or Bundle Line

135”

4-Out Capability

FOR ADDITIONAL ADD ONS, SEE G3™ STACKER FEATURES & UPGRADES

eXT™ Corrugated Stacker Front End

Fully electric and fully integrated front end system.

This patented and patent-pending front end system allows for EXTreme RDC speeds, sheet control and scrap removal.

Capable of 20,000 KPH

Internal Process Cameras

No Chains or Hydraulics

Adjustable NIPs

The eXT™ is part of the fully electric eSERIES™ equipment line.

eXT™ Stacker Front End Features:

Scrap Control System

Order Recipe Recall

Supreme Control & High Speed

Fast, Reliable Set Up

Patented & Patent-Pending

No Pit or Floor Work

Roll Out Capable

Modular Design

Ease of Access

eTAMP™ ServoTamp

Easily adjust all components of the hopper using the A.G. HMI.

Don’t pause production! With the eTAMP™ system, the operator no longer needs to set up tampers in the hopper.

The eTAMP™ is part of the eSERIES™ equipment line.

eTAMP™ Servo Tamp Features:

Adjustable at Full Production Speeds

Linear Motor with Multi-Axis Servo Control

Fully Electric

Automatic Backstop, Tamper and Dividers

Intuitive Operator HMI System

Fast, Reliable Set Up

Order Recipe Recall System

Increased Operator Safety

Divert & Separate System (DSS)

Automatically divert and separate at full production speeds

Diverting adjustments with the swipe of a finger! With the DSS you can automatically divert and separate at full corrugated stacker speeds, efficiently and effectively.

Divert & Separate System Features:

Automatic Divert & Separate Set Up

Up to 4-out Shingling Capability

Adjustable at Full Production Speeds

Order Recipe Recall System

Simple Swipe Touch Screen Set Up

Fast, Reliable Set Up

GHG Partner | Corrugated Stackers Solutions

Founded in 1996, A.G. Stacker, Inc. is an innovator in corrugated material handling equipment and technology. Located in the heart of the Shenandoah Valley Virginia, A.G. manufactures all equipment in their USA 60,000+ sqft facility. A.G. offers a full line of innovation: stackers, bundle breakers, load formers, upgrades & retrofits, conveyors, and integrated technology.

Greene House Group is the exclusive representative for A.G. Stacker Inc. in western United States.