Corrugated Conveyor Manufacturer

Keep Your Production Moving…

Keep your production moving safely and successfully with precision solutions from conveyor manufacturer’s A.G. and Dücker-Ringwood Automation. Increasing throughput, productivity, and efficiency, these conveyor systems get your goods through the converting process and out the door intact and in time. Contact our team today to discuss your production needs!

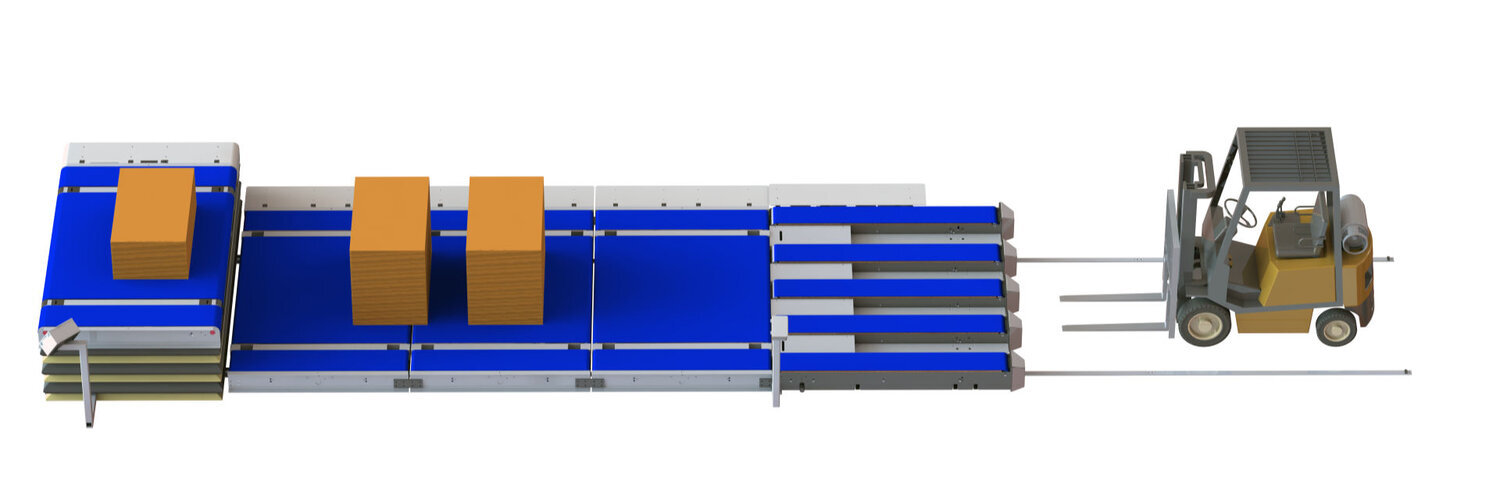

Infeed Conveyor System

The Ergonomic Infeed Solution

This patented Infeed Conveyor System is a semi-automatic, ergonomic solution that eliminates the pain points and risks associated with manually fed machinery. Building on the patented X12™ no-pit lift table, this infeed conveyor uses a powered fork truck station and all mesh top conveyors to move product up to the X12™. Once on the X12™, the lift automatically adjusts top-of-stack to the ideal operator height for operator feeding, minimixing stooping and straining by the operator.

Infeed Conveyor Features & Advantages:

Accessible Forklift Station

Customized to Plant Needs

Convenient Operator HMI

Ergonomic Sheet Feeding

Indexing & Queue Modes

Heavy Duty

Semi-Automatic

Pitless

Flexible

Patented

X12™ Pitless Lift Conveyor Solution

Mounted on the X12 lift, the bundle conveyor system with patented ball belt technology allows product to be discharged in any direction. More information in the BCS product section next!

Patented. Pit-less. Flexible. Integrated. Safe.

No pit needed – saves time & money, less maintenance, allows for adjustment in floor plan

Reinforced and balanced for heavy loads.

Patented technology!

Fully Integrated: no need for another HMI

Highly Efficient: discharges in seven seconds, not 10, 15, or 20

Safety First: incorporated with stacker’s ISS to keep operators safe

Less Stress: less vertical movement for the stacker

Easily Retrofitted: add to existing stacker to improve performance

Standard Sizes: 115”, 125” – other sizes available upon request

Bundle Conveying System (BCS)

The X12™ Vertical Lift Conveyor brings efficiency and safety to your corrugated material handling process, without pits! This fully automatic system is the solution you need to improve productivity, safety and stacker efficiency. The X12™ Pitless Lift Conveyor Table allows your stacking and feeding operations to run continuously and removes the need to wait for discharge and stacker reset. Add in the safety and financial benefits of needing no pits and the X12™ Lift Conveyor is a proven solution to streamline your infeed and outfeed process.

X12™ Pitless Lift Conveyor

Bundle Line Conveyor Manufacturer

Most commonly configured as two stages: X12 + 2nd stage option (Pop Up or Ball Belt)

Retrofittable to non-A.G. Stackers (subject to engineering review)

Pop Up – Roller conveyor in the through direction with mesh pop-ups that can discharge left or right

High Speed Hopper Ejector requires BCS

Move Bundles or Stacks in Any Direction, Downstream

Designed for safety, speed and flexibility, A.G.’s fully integrated Bundle Conveyor System easily moves bundles or stacks, in any direction, downstream. This system is built on the patented X-12™ lift and is capable of conveying stacks and/or bundles downstream efficiently and effectively. Accumulation of multiple stacks or bundles on conveyor possible if required.

A brand new and patented ball belt transfer table is available as a Stage 2 option for the BCS and includes the capability of running multiple bundle lines.

Ball mesh that allows product to be discharged in any direction, mounted on the X12 lift for convenient, reliable performance without rollers.

Stabiltrack® Corrugated Conveyor System

Stabiltrack® Corrugated Conveyor System

The Stabiltrack® corrugated conveyor with integrated longitudinal pusher permits you to form stack arrangements for your format pallets or to double the load units for the transfer car. This increases the throughput enormously. In case of high-performance plants, doubling counters bottlenecks. Depending on the layout, shuttle cars can be used to receive the stacks as they are moved off the corrugator.

Stabiltrack® Features:

High Throughput

Double load units

Reduce bottlenecks

Precise stack arrangements

Storage Conveyor Manufacturer

Storage Corrugated Conveyors

For gentle transport of the stacks we use our tested Stabiltrack® corrugated conveyor, which has been equipped with modular plastic chains made of acetal.

Conveyor System Features:

Low-maintenance and easy to service

Frequency-controlled drive

Optimal space usage by double occupancy of storage lanes

No sheet-walk effect

Less waste caused by damage

Safety for the operator

Energy savings - sections run only when needed

GHG Partners | Corrugated Conveyor Manufacturers

Greene House Group is the exclusive representative in western United States for A.G. Stacker Inc. & Dücker Ringwood Automation.